Over 100,000 people die every year from natural disasters. Their families have often lost everything they own, and they can’t afford to give their loved ones the funeral they deserve.

Our casket provides an affordable, sustainable, and dignified solution for victims of natural disasters. It packs flat for expedited deployment and provides a platform for volunteers and professionals to collect and care for victims with safety and sanitation in mind.

The system arrives flat on a pallet, with plywood panels pre-adhered onto a waxed cardboard membrane. The plywood adds structure to the casket while the waxed cardboard lining creates a leathery soft interior and a leak resistant surface. The large flat backboard can be used to retrieve bodies and as a work surface for autopsies or emergency medical procedures.

Once the medical professionals are finished with the body, the backboard is closed inside the two other portions and is carried to the grave site where families may hold a funeral service. As an option, the top half of the casket can be temporarily removed so that family members can view the body during the service.

The cardboard is die cuts and scores the folding pattern straight into the cardboard, making it easy for volunteers to assemble on site with little to no instruction. As a hinge, the cardboard provides surprisingly strong structural support. On our first scale prototype, we had planned to use metal brackets to reinforce every joint, but found that only half of them were necessary.

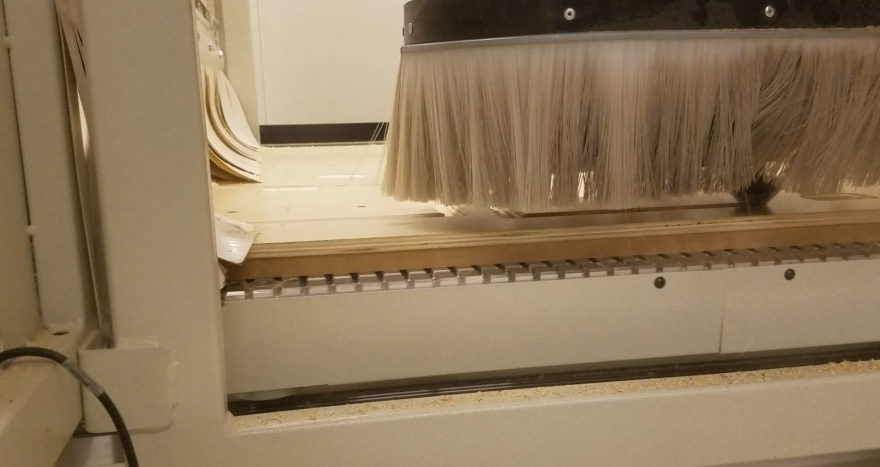

It takes only 1.5 sheets of half inch 4'x8’ plywood to make each casket. We use a miter bit to trace our profiles which makes edges softer and easier to handle, while also reducing the amount of steel we need to make our brackets. During the same CNC process, we cut holes and slots for handle attachment, as well as the holes for our brackets, which are embedded with t-nuts so that volunteers can assemble everything using only an allen wrench.

Polyester ropes are threaded through each piece of plywood before they are placed on the gluing jig. They are tied off in a modified quadruple fisherman’s knot, which functions both as a splicing mechanism and as a handle for carrying the coffin after assembly. When all these pieces are in place, the non-waxed side of the cardboard is mounted onto the plywood using an industrial spray adhesive. For wet disasters, a spray-on wax or poly finish can be applied externally after the adhesive has fully cured. Our brackets are water-jet from 12-gauge steel, and are pre-attached to one side of the casket to greater simplify the assembly.

Using plywood and cardboard as a composite has proven to be a robust and easily deployable system. We are using extremely common materials in a way that they’ve never been used before, and throughout this process we have seen the potential to use the same system for quickly erecting other small structures such as refugee shelters, sheds, and other non-conditioned outdoor spaces

http://www.core77.com/projects/60865/Disaster-Casket-An-Affordable-Flat-Pack-Burial-Solution-for-Deaths-Caused-By-Natural-Disaster